MAN Energy Solutions

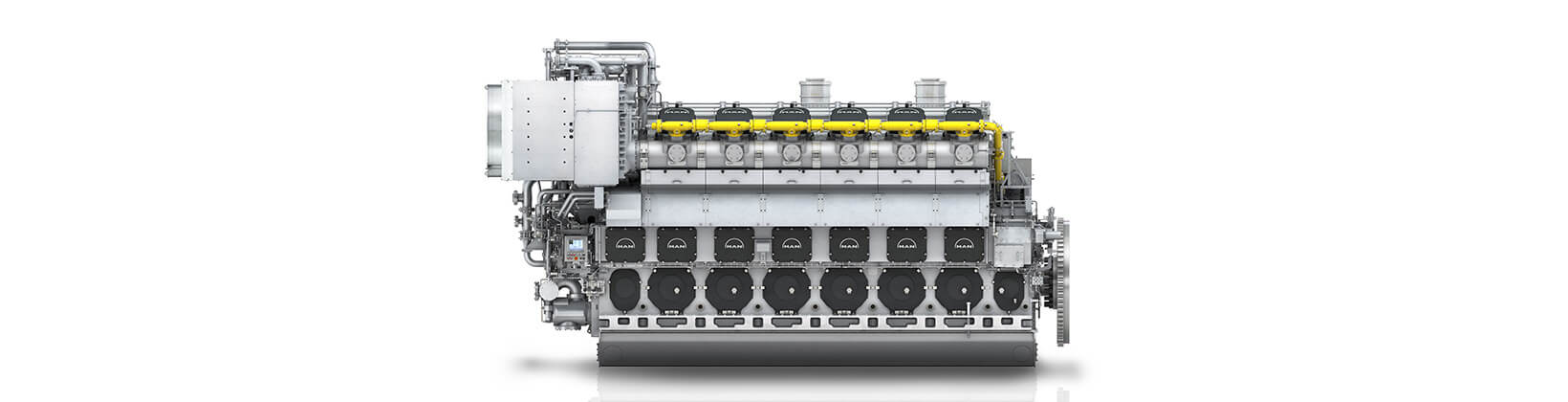

MAN Energy Solutions is one of the world’s leading suppliers of large diesel and gas engines and turbomachinery. With headquarter in Germany, MAN Energy Solutions employs over 14 000 people with 120 service locations worldwide.

We are proud that we were able to simplify the processes for the four-stroke division of MAN Energy Solutions with our processes easier with our software.

Start of the collaboration with B&W Software

The collaboration between MAN Energy Solutions ( then MAN Diesel & Turbo) and B&W began in 2013 with Guido Dresemann.

At the time, MAN Energy Solutions was looking for a developer for the attribute manager in Creo. The idea was to maintain metadata directly on the CAD model instead of entering it in isolation on the drawing. This was one of the cornerstones for model-based engineering.

The Attribute Manager not only provides a user-friendly interface for the maintenance of parameters, it also supports the designer with stored lists and rules, thereby increasing data quality in Creo and all connected systems, such as Windchill and SAP, to which this data is transferred.

The problem – shipyard connections and

screw tightening values

In contrast to series production in the automotive environment, plant engineering requires customer-specific documents for project handling and assembly for each new order due to the large number of variants.

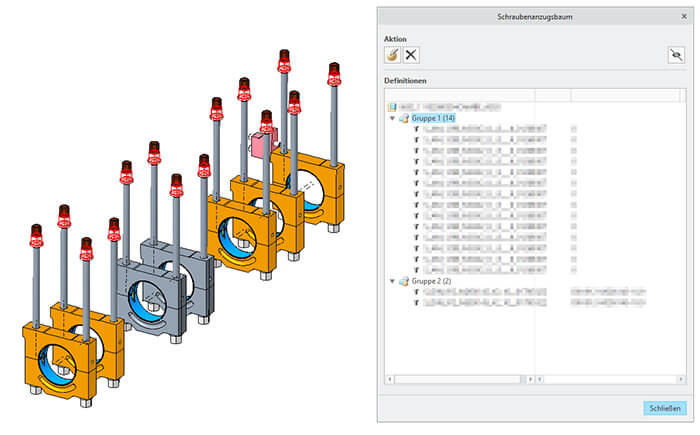

This includes both the so-called installation drawing with the shipyard connections for operating the engine and the overview for screw tightening values for all screw connections that deviate from the standard torque for functional reasons.

The preparation of these documents was quite time-consuming. This is because the required information can only be found as free text on the assembly drawings and parts lists. Sometimes, ongoing technical changes to the product also had to be taken into account. In addition, there was the already mentioned high number of variants, which made a “copy paste” from existing projects possible in the rarest of cases.

The Solution

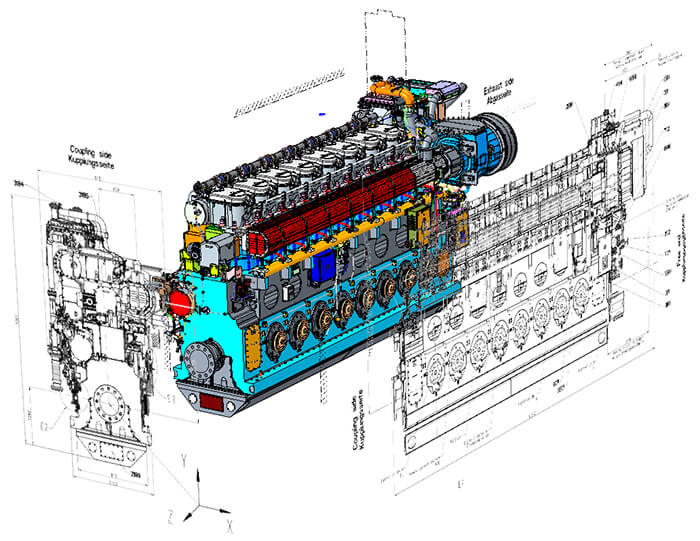

Engineers Sven Klaua and Jürgen Micheler (MAN Energy Solutions) had an idea: why not enter the required information directly in the 3D model? That way, it could be reused and retrieved quickly and reliably in the subsequent process. For the installation drawing and bolt tightening values, storage as component parameters with the support of a user interface analogous to the already existing attribute manager was the obvious choice. The vision of the model-based approach was taken up, thought through further and projected.

In addition to the new user interface for maintaining the parameters, an additional application was required to read the parameters from the customer-specific overall motor model and display them in configurable tables.

B&W Software developed this functionality in a clear, flexible as well as easy-to-use and configurable software application.

These measures alone were able to reduce the effort required to create an installation drawing by 80%. By adapting the assembly process, it was even possible to completely eliminate the need for screw tightening overviews.

However, this was not the end of the vision of the idea creators as to what should happen to the data in the with the data in the 3D models:

For the purpose of visualization, one derives a 3D motor model. Depending on the medium, a colored arrow (for media inlet and outlet respectively) now marks the connections. With a specially developed collection function, a coordinate cloud can be derived from the said overall motor model. This can be used as a lightweight file for 3D plant design. B&W Software was also able to provide support here with the development of the application.

In this way, B&W Software has developed another real added value from the solution – in addition to the increase in efficiency – which did not exist before and which can support MAN Energy Solutions’ future customers in their planning.

Conclusion

In addition to the excellent cooperation between MAN Energy Solutions and B&W Software, the support provided as early as the task specification stage and the implementation described is justifiably a success story. Once again, it became clear that B&W Software has practitioners at work who, in addition to the actual task – software programming – contribute their own experience in the area of design and development.

MAN Energy Solutions already has the next ideas for projects with B&W Software. For example, an expansion of the attribute manager for mass maintenance of metadata is on the agenda.

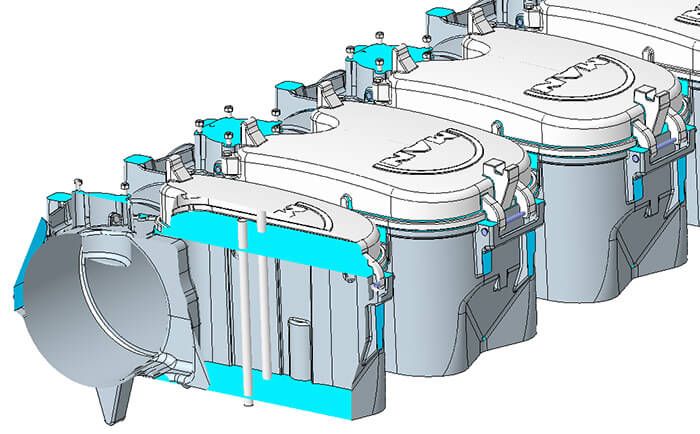

Weiteres Projekt: Multifunktionelle

Shrinkwrap-Modelle

Ein Baustein für ein schlankes, leicht zu bearbeitendes, aber dennoch

konfigurierbares Gesamtmotormodell im Creo sind vereinfachte

Komponenten, wie z.B. Shrinkwraps der Hauptbaugruppen.

Hier können Sie mehr darüber erfahren.