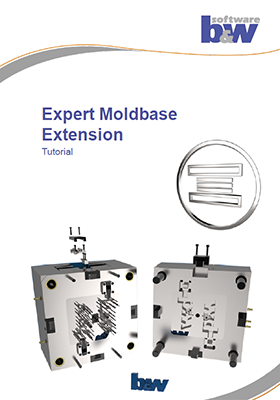

Power for your Moldbase Design Expert Moldbase Extension

- Automated tool design

- Standards of common standard part manufacturers available

- Cooling generation with collision test

- Automatic trimming of ejector pins

- Create BOMs and export them to Excel

- Maintain and assemble your own library parts

Benefits for your company

With Expert Moldbase Extension (EMX) as a module fully integrated into Creo Parametric, you can extend your software portfolio in order to standardize or automate design tasks in the field of injection molding tools to a large degree, thus allowing you to focus more on your core tasks.

By integrating standard part libraries from all common manufacturers and providing numerous intelligent templates, you can handle tasks in the areas of tool design and standard part installation quickly and flexibly. You will be supported by user-friendly dialogs and input assistance, which offer you the available options as appropriate. By offering extensive analysis tools, users outside the design department also benefit directly of the automatically derived results.

Furthermore, the software naturally supports you when transferring the design data to the production area, both in the classic drawing derivation and in the digital and drawing-free transfer of the product and manufacturing information (PMI).

-

Timesaving

EMX eliminates the time-consuming import of external design data, as standard parts are generated and installed in the native Creo format, and the corresponding sections are generated according to the manufacturer's specification.

-

Simple

You can easily select and install standard parts from various manufacturers using uniform installation conditions and options.

-

Standardized

The high variability of the software allows you to centralize company policies, captures design knowledge and reduces manual repetitive errors.

-

Integrated in Creo

From plate assembly to export of the BOM, the software is embedded in the design process with Creo Parametric. The integration with Windchill completes the range of functions.

Videos

Here you will find a selection of current videos that will

bring EMX closer to you.

Functionalities

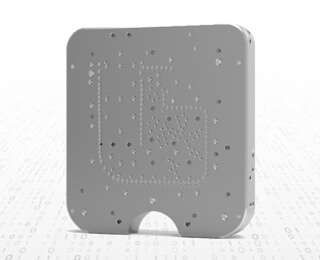

Assemble Components

Screws, pins, guides, cooling, ejectors etc. are assembled via a standardized dialog. These components can be modified and reused after assembly. Information on standard parts can be accessed via a direct web link to the manufacturer’s websites.

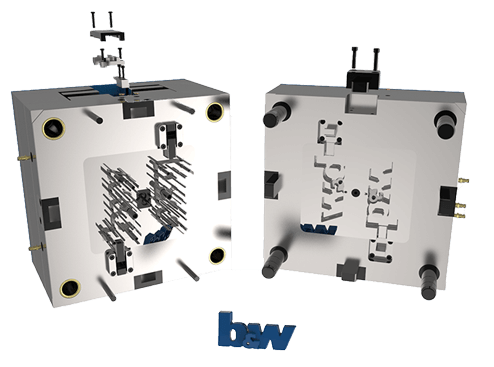

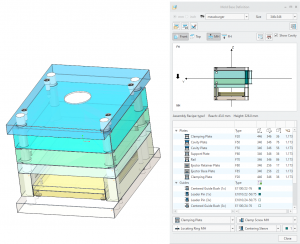

Define Tool

Standardised panel assemblies can be created via the mold base definition.

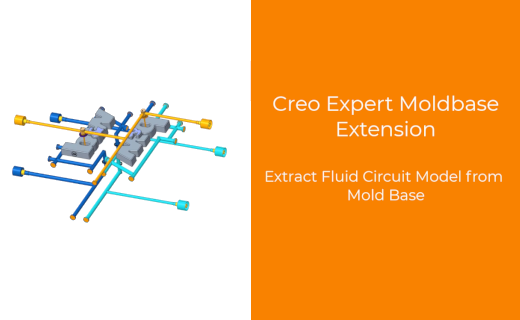

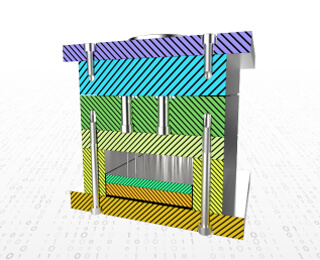

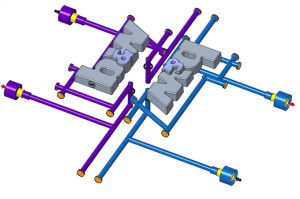

Generate Cooling Circuits

Complex cooling circuits with connection components can be generated by using curve sketches.

In addition, it is possible to perform a collision test with the surrounding geometry.

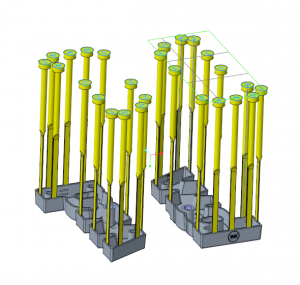

Place Ejector Pins

Ejector pins can be placed directly on points. It is possible to contour the pins directly on the article.

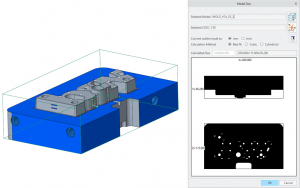

Calculate Model Size

This function enables the automatic calculation of the model sizes of all parts in the tool structure.

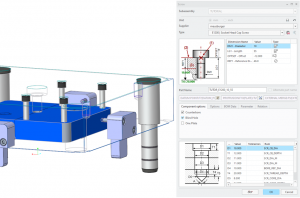

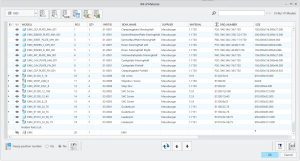

Manage BOMs

The BOM dialog can be used to manage parameter-based BOMs. The dialog provides additional tools that enable an export to Excel, the placement of drawing balloons or size calculation.

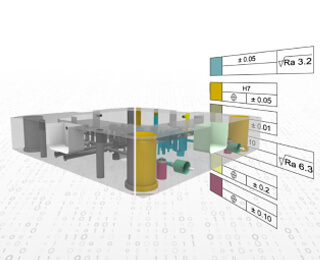

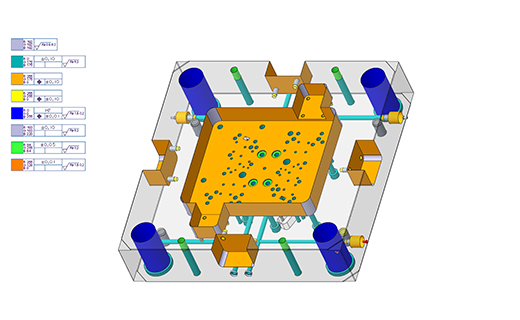

Color Coding in Mold Design

Color Coding enables the provision of product and manufacturing information in the form of color assignments. This information is machine-readable and is therefore available in subsequent processes, such as NC- and CMM-programming. EMX is prepared for use with our SmartMBD tools to enable automatic coloring of surfaces based on the surface function.

Learn more about Color Coding with Expert Moldbase Extension and SmartMBD-Tools from B&W Software.

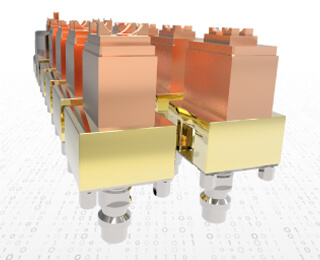

Component Partner in EMX

For the insertion of standard parts (e.g. cooling components, guide components, ejector pins, plates and much more)

the libraries of the following suppliers are available to you, among others:

Additional manufacturer: FCPK, PCS, Progressive Components, Ramseier, DMS, OMNI Mold Systems, TVMP, LKM, Misumi, Futaba, Stäubli, OPITZ and on request.

Technical details

Find out about the supported Creo® versions

in our product calendar.

More information?

Request Demo Version

Have we aroused your interest?

Then you are welcome to request a demo version from us here.